Difference Between Upstream, Midstream and Downstream

The Upstream, Midstream, and Downstream refer to the different stages of the petroleum value chain, each with intricate procedures and separate operational objectives. Despite their differences, these sectors are deeply interconnected, working together to overcome the challenges of exploration, production, transportation, storage, refining, and distribution of oil, natural gas, and their derivatives. Curiously, the terms 'Upstream' and 'Downstream' have roots outside the oil and gas industry, drawing inspiration from the Kanban methodology—a system originally developed to optimize workflows in manufacturing. Thus, understanding this origin provides valuable insights into how the industry’s segmentation reflects efficiency-driven principles. But are you familiar with [...]

Why Downstream Operations are the Heart of Petroleum

According to McKinsey, oil refineries can process nearly 100 million barrels of crude oil globally daily. Thus, given the presence and scalability of oil-derived products, downstream operations—industries responsible for transforming crude oil into fuels—may be the heart of the petroleum value chain. In comparison, the heart’s role doesn’t limit itself to pumping blood just as a petrochemical plant does to refining oil. Both are crucial to filtering impurities and fueling energy for the whole organism. Downstream: The heart of the Petroleum Value Chain Deepening the analogy, the heart receives deoxygenated blood from the body, sends it to the [...]

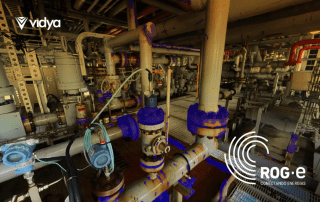

ROGe featured paper: Digitizing Corrosion Management and Fabric Maintenance

Vidya will present two technical articles regarding our deeptech solutions at ROGe 2024. The second presentation, which takes place on September 23rd, will discuss the Digital Fabric Maintenance application. The article showcases the application’s tracked and proven impact on the oil and gas industry. Get to know our article better in this blogpost: ''A case study of an alternative approach to digitize the management of external corrosion and fabric maintenance workflow of an offshore installation'' Corrosion poses a significant and inherent threat to the Oil and Gas industry, leading to equipment failure and production losses. For this purpose, [...]

Making the most of POB on offshore assets

Offshore industrial operations are risky environments for on-site workers. This group of people, referred to as People on Board (POB), is responsible for inspecting, executing maintenance, and ensuring operational safety in the facility. However, oil and gas facilities may present risks that result in incidents such as explosions, dropped objects, oil leaks, and others. Besides that, unplanned events happen, requiring workers to have an immediate response to mitigate the occurrence. The International Association of Oil and Gas Producers reported a 36% increase in offshore fatalities from 2020 to 2021. In this context, oil industries have to deal with limitations [...]

Understanding Dropped Object Prevention for Energy Industries

In 2016, dropped objects from Offshore Oil facilities resulted in 255 worker fatalities in the United States, according to the Bureau of Labor Statistics, an alarming statistic that made clear the urgency of a curious, but important safety protocol that industries needed to adopt: fighting gravity. However, these incidents are far from inevitable and can be significantly reduced through a robust Dropped Object Prevention program. And, considering the scale and complexity of the energy industry’s operations, these programs became a fundamental piece of Industrial Safety and Risk Management. But what defines a Dropped Object? What is a Dropped Object? [...]

5 Essentials of Hull Damage Prevention for ships and FPSOs

Hull damages such as cracks and discontinuities can lead to oil leaks, implicating direct emergency costs surpassing USD 50,000,000, according to Brazil's National Petroleum Agency. From oil spills to accidents, the consequences of hull damage on oil and gas operations are far-reaching. Besides that, hulls are the exoskeleton of offshore units, requiring regular, accurate, and efficient maintenance procedures to address the excessive wear and tear, cracks, and anomalies that these structures are exposed to. Ensuring adequate maintenance and repairs demands inspection procedures that often require rope access techniques. Even though it is a common practice, it exposes inspectors to complex [...]

Computer Vision 101: How can AI see things?

A world where computers can understand the environment around them simply by looking. This isn't science fiction anymore. It’s the new frontier of artificial intelligence called Computer Vision. It can perceive its surroundings and interpret visual information to identify objects, colors, shapes, and areas. This technology consists of a model that learns information from multidimensional data, such as images or videos, enabling machines to develop a visual perception like humans. Today, Computer Vision systems can analyze vast amounts of visual data with incredible accuracy. But how exactly was Computer Vision developed? How does it work? And what are the [...]

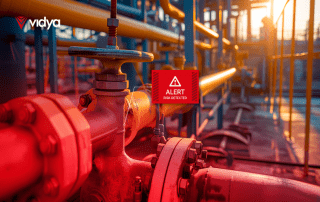

How to optimize Industrial Safety and Risk Management

The International Association of Oil and Gas Producers reported a 36% increase in offshore fatalities from 2020 to 2021. This concerning rise underscores the inherent safety challenges of the industry. Certainly, this sector is subjected to safety threats due to the complex processes and hazardous environments in which it operates. For this reason, high-complexity facilities such as oil and gas need to target safety and risk assessments as fundamental pieces of operational management. But what are the main concerns of the oil and gas industry regarding risk management? Concerns regarding risk management in the O&G Industry [...]

The Future Lies in the Past: Embracing Brown Fields for Tomorrow’s Energy

A 2011 study by IHS Cambridge Energy Research Associates reported that approximately two-thirds of global daily average oil production comes from brown fields and that the percentage is increasing over time. Indeed, it’s evident that mature fields have become a fundamental piece of the petroleum exploration sector, but what exactly are mature fields? According to Parshall (2012), brown fields, also known as legacy fields, are defined by years of production and aging infrastructure. Indeed, for a field to be considered brown, it had to produce more than 50% of its established proved plus probable resource estimates or have produced for [...]

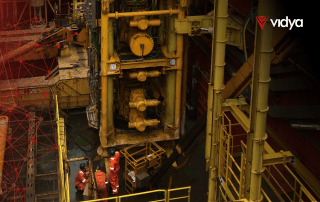

Exploring the Depths: Understanding Offshore Oil Drilling

Until 1894, we didn’t know extracting crude oil from subsea environments was possible. This changed when the lure of offshore production enticed Henry L. Williams and his associates to build a pier 90 meters out into the Pacific — and assemble a standard cable-tool rig on it. Since then, oil extraction has evolved in unprecedented ways. In recent years, new technologies have emerged as powerful tools for addressing the inherent challenges of exploring previously unreachable resources. Indeed, subsea drilling still represents a complex operation that requires advanced techniques and skilled teams to achieve optimal efficiency and safety. And, despite the [...]