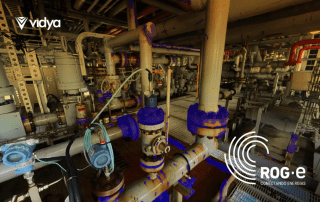

ROGe approved paper: Digitizing Corrosion Management and Fabric Maintenance

Vidya will present two technical articles regarding our deeptech solutions at ROGe 2024. The second presentation, which takes place on September 23rd, will discuss the Digital Fabric Maintenance application. The article showcases the application’s tracked and proven impact on the oil and gas industry. Get to know our article better in this blogpost: ''A case study of an alternative approach to digitize the management of external corrosion and fabric maintenance workflow of an offshore installation'' Corrosion poses a significant and inherent threat to the Oil and Gas industry, leading to equipment failure and production losses. For this purpose, [...]

Making the most of POB on offshore assets

Offshore industrial operations are risky environments for on-site workers. This group of people, referred to as People on Board (POB), is responsible for inspecting, executing maintenance, and ensuring operational safety in the facility. However, oil and gas facilities may present risks that result in incidents such as explosions, dropped objects, oil leaks, and others. Besides that, unplanned events happen, requiring workers to have an immediate response to mitigate the occurrence. The International Association of Oil and Gas Producers reported a 36% increase in offshore fatalities from 2020 to 2021. In this context, oil industries have to deal with limitations [...]

How is AI applied to corrosion detection?

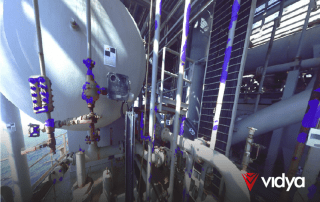

Corrosion detection is a challenging, risky, time-consuming, and expensive process. According to NACE, the global corrosion cost is estimated to be US$2.5 trillion, equivalent to 3.4% of the global GDP (2013). On top of that, it requires workers to inspect every edge of an enormous environment full of flammable hydrocarbons. However, the use of AI is reshaping this practice. In this context, AI-driven corrosion detection offers a safer and more sustainable method of addressing corrosion by providing a holistic perspective on Asset Integrity Management with 3D models, predictive algorithms, data contextualization, and Machine Learning. Thus, this blog analyzes how AI [...]

Developing an Effective Corrosion Prevention Strategy for Mining Operations

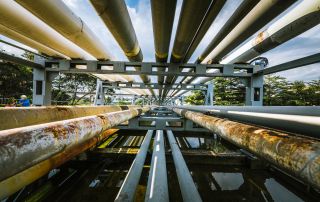

Intro Corrosion consists of constant material degradation by chemical or electrochemical reactions with its environment. Indeed, heavy corrosion damage can lead to extended unplanned shutdowns, decreased safety, and increased environmental exposure. And, while corrosion progression doesn’t stop, asset activities must be paused to address degradation and anomalies. In this context, mining structures are exposed to harsh environmental conditions, including moisture, acidic or alkaline substances, and abrasive materials, which accelerate corrosion. This being said, developing an effective corrosion prevention strategy is crucial to mitigate the impacts and costs of corrosion. A two-year global study released at the CORROSION 2016 conference [...]

Why traditional Corrosion Management methods are becoming obsolete

Offshore Oil operations are constantly threatened by an inevitable factor: Corrosion. Heavy corrosion damage can lead to extended unplanned shutdown times, decreased safety, and increased environmental exposure. This is why Oil and Gas companies struggle with traditional Corrosion Management methods becoming obsolete. However, corrosion management isn’t an easy task, involving locating, prioritizing, and treating corrosion signs along +300,000m² areas. Besides that, while operations need to execute interventions, they need to deal with limited maintenance time, budget constraints, and costly downtime. For this reason, the sector’s complexity requires an alternative method of addressing corrosion. The Importance of Corrosion Management [...]

Challenges of Corrosion Under Insulation

Intro Corrosion under insulation (CUI) is a pervasive problem in industrial process units that can lead to serious consequences if left unaddressed. It occurs when moisture becomes trapped between the insulation material and the metal surface, leading to accelerated corrosion. In this blog post, we will explore what CUI is, the risks it poses to process units, and the costs associated with it. What is Corrosion Under Insulation? Corrosion under insulation refers to the corrosion that occurs beneath insulation materials used to protect industrial equipment and pipelines. When moisture is present within the insulation, it creates a corrosive environment that [...]

Maximizing Efficiency and Cost Savings with Effective Coating Management

In today's highly competitive business landscape, maximizing efficiency and cost savings is crucial for any organization that wants to succeed. One area where this can be achieved is through effective coating management. Whether it's in the manufacturing, construction, or transportation industry, proper coating management can help businesses save time, money, and resources while ensuring high-quality results. From selecting the right coating materials to implementing a robust maintenance program, there are many steps that can be taken to streamline the coating process and minimize waste. In this article, we'll explore some of the best practices for coating management and how they [...]

Paper vs Digital Inspections

Intro Oil and Gas operations pose unique challenges to their operations when the matter is inspection and maintenance. Since this kind of activity involves a variety of risks and complexities, it is not uncommon to find field workers filling out paper reports, and walking around the facility looking for potential problems. This is a traditional-manual method, on which oil and gas companies relied throughout the years when performing risk assessments with the goal of preventing potential hazards that could compromise the continuity of the operation. Meanwhile, digital transformation has been disrupting the way things are done with increasingly advanced [...]

The Corrosive Process in the Oil and Gas Industry

Intro Corrosive processes are one of the main challenges for the oil and gas industries around the world. From the extraction process to refining and transportation, corrosion is an ongoing element in oil and gas plants. Besides being a high-risk problem for operators in the field, corrosion is also responsible for a large cost. According to NACE, the cost of corrosion prevention in an industrial environment is around 49 billion dollars, with at least 50% of this amount referring to atmospheric corrosion. In this blog we will talk about the main challenges and impacts generated by corrosion in the oil [...]

Structural Integrity: aspects of one of industry’s main challenges

Intro The structural integrity of a piece of equipment or part is essential for the proper functioning of an industrial operation. To ensure safety within industries, it is in the operation and maintenance phase that integrity managers have the great challenge of ensuring that all equipment in operation can maintain their levels of productivity, safety, and performance through continuous monitoring and corrective actions, if necessary. In this blog, we will talk a little about the main characteristics of problems related to the structural integrity of equipment, and how these problems can be addressed. What is it Structural integrity refers to [...]