The Future Lies in the Past: Embracing Mature Fields for Tomorrow’s Energy

A 2011 study by IHS Cambridge Energy Research Associates reported that approximately two-thirds of global daily average oil production comes from mature fields and that the percentage is increasing over time. Indeed, it’s evident that mature fields have become a fundamental piece of the petroleum exploration sector, but what exactly are mature fields? According to Parshall (2012), mature fields are defined by years of production and aging infrastructure. For a field to be considered mature, it had to produce more than 50% of its established proved plus probable resource estimates or have produced for more than 25 years. In this [...]

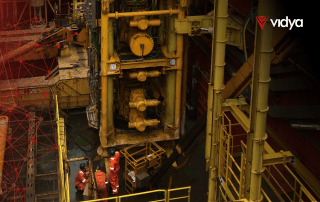

Exploring the Depths: Understanding Offshore Oil Drilling

Until 1894, we didn’t know extracting crude oil from subsea environments was possible. This changed when the lure of offshore production enticed Henry L. Williams and his associates to build a pier 90 meters out into the Pacific — and assemble a standard cable-tool rig on it. Since then, oil extraction has evolved in unprecedented ways. In recent years, new technologies have emerged as powerful tools for addressing the inherent challenges of exploring previously unreachable resources. Indeed, subsea drilling still represents a complex operation that requires advanced techniques and skilled teams to achieve optimal efficiency and safety. And, despite the [...]

Why predictive maintenance isn’t always an answer

Intro Predictive maintenance has proven to be an effective methodology for enhancing the lifespan of valuable assets in the industrial sector, as it allows companies to predict when equipment is likely to fail or stop. This way, proactive measures can be taken to prevent downtime and reduce maintenance costs. Besides that, a November 2021 report from IoT Analytics estimated that the $6.9 billion predictive maintenance market would reach $28.2 billion by 2026. This showcases the immense potential this technology has, allowing companies to optimize their outcomes while reducing downtime. However, if this technology isn’t adequately implemented, [...]

Benefits of Predictive Maintenance for Christmas Tree Equipment in the Oil and Gas Industry

Predictive maintenance is a modern approach to equipment maintenance that aims to predict potential failures and prevent them before they occur. In the oil and gas industry, the importance of maintenance cannot be ignored, as equipment downtime can result in significant financial losses and a decrease in production, as well as a safety risk. For example, one of the most relevant equipment for upstream oil and gas industries during the product extraction phase is the Christmas Tree, which is largely responsible for controlling productivity and safety in the operation. In other words, a failure that impairs its operation can [...]

Predictive Maintenance for a more optimized and less expensive mining operation

The hostile environment and complex operation of mining industries are major drivers of the main problems faced by the sector: unplanned equipment downtime and high operational maintenance costs. Because of this, the recent technological advances have begun to deliver more precise solutions to the challenge of keeping up with the industry's demand for its products while seeking to reduce unnecessary expenses in the operation. In this context, the predictive maintenance process will be presented and deepened in order to understand how it can be the solution to increase the efficiency and profitability of mining industries by facilitating data management [...]

Predictive maintenance to manage corrosion and reduce failure on Steel Industries

The hostile environment of steel industries is a major driver of the main problems faced by the industry: corrosion and low efficiency in the maintenance of structures and equipment. Knowing this, it is necessary to understand how to adapt the operation and data analysis processes to ensure that the value drawn from them is greater than the consequences generated by the environment. In this context, the predictive maintenance process will be presented and deepened in order to understand how it can be the solution to increase the efficiency and profitability of steel industries by facilitating the management of corrosion [...]