Las diferencias entre Upstream, Midstream y Downstream

Upstream, Midstream y Downstream són términos utilizados para representar las distintas etapas de la cadena de valor del petróleo. En este contexto, aunque cada etapa tenga procedimientos específicos y objetivos diferentes, todas están profundamente interconectadas. Juntas, hacen frente a los desafíos de exploración, producción, transporte, almacenamiento, refinación y distribución de petróleo, gas natural y sus productos derivados. Curiosamente, las expresiones Upstream y Downstream no nacieron en la industria del gas y petróleo. Ellas tienen su origen en la metodología Kanban: un sistema originalmente proyectado para optimizar y reducir flujos de trabajo en manufactura. Por eso, comprender este origen permite [...]

Vidya Technology e Alutal apresentam nova geração de Hardware para integridade industrial

30 de Junho de 2025 Vidya Technology, referência em soluções digitais para integridade industrial, anuncia sua parceria com a Alutal, empresa líder na fabricação de sensores de temperatura e distribuição de equipamentos para instrumentação de processos industriais. Unindo seus lemas — “Operate with ease” e “Measure & trust” (em tradução livre: “Opere com Facilidade” e “Meça com Confiança”)— a colaboração entre as duas empresas dá origem à linha Alutal powered by Vidya, que oferece hardware para o monitoramento de corrosão inovador, confiável e pronto para os desafios da Indústria 4.0. Apesar de ser conhecida por suas soluções de Digital Twin [...]

Partnership Announcement: Vidya Technology and Alutal Introduce a New Generation of Hardware for Industrial Integrity

June 30, 2025 Vidya Technology, a leading provider of digital solutions for industrial integrity, announces its partnership with Alutal, a major manufacturer of temperature sensors and distributor of instrumentation equipment for industrial processes. Combining their mottos — “Operate with ease” and “Measure & trust” — the collaboration gives rise to the Alutal powered by Vidya product line, offering innovative, reliable hardware for corrosion monitoring, ready to meet the demands of Industry 4.0. Though Vidya Technology is known for its Operational Digital Twin and Artificial Intelligence solutions, its deeptech roots are closely tied to hardware development. It all began when the [...]

Integridade de Ativos e a conformidade com a NR-13: Tudo o que você precisa saber

Em indústrias de grande porte, como óleo e gás, plantas químicas e mineiração, as instalações operam sob condições de alta pressão, temperaturas elevadas e riscos constantes. Nesse contexto, cumprir normas regulatórias não é uma exigência burocrática — é uma necessidade técnica. A integridade dos ativos, a segurança das pessoas e a continuidade operacional dependem diretamente da aderência às exigências normativas, especialmente no que diz respeito a equipamentos que operam sob pressão e outras infraestruturas críticas. No contexto da indústria de óleo e gás brasileira, a Norma Reguladora 13 (NR-13) é o código regente para todas as empresas do setor. Este [...]

Iron Roughneck: A Critical Component in Oilfield Operations

Efficiency and safety are non-negotiable for oil and gas operations. Advanced machinery takes on the toughest tasks to keep operations running smoothly and reliably—none more crucial than the iron roughneck. Interestingly, the term “iron roughneck” isn’t just about equipment; it’s also how American oil workers proudly refer to themselves, embodying the grit and resilience required in the field. But what exactly is an iron roughneck in oilfield operations? How does it function, and what challenges arise in keeping it operational? This blog will explore its critical role, the maintenance difficulties it presents, the power of predictive analytics in preventing failures, [...]

Condition-Based vs Reliability-Centered Maintenance

Condition-Based Maintenance and Reliability-Centered Maintenance are both popular and often confused concepts in Asset Integrity Management. Indeed, they share some common goals: minimizing downtime, reducing maintenance costs, and ensuring the reliability of critical assets. However, understanding the distinctions between these two approaches is crucial for any industry looking to optimize maintenance strategies. Condition-Based Maintenance (CBM) Condition-Based Maintenance consists of a predictive maintenance approach that analyzes the historical performance data of machines to forecast when one is likely to fail, limit the time it is out of service, and identify the root cause of the problem. The idea here [...]

5 Essentials of Hull Damage Prevention for ships and FPSOs

Hull damages such as cracks and discontinuities can lead to oil leaks, implicating direct emergency costs surpassing USD 50,000,000, according to Brazil's National Petroleum Agency. From oil spills to accidents, the consequences of hull damage on oil and gas operations are far-reaching. Besides that, hulls are the exoskeleton of offshore units, requiring regular, accurate, and efficient maintenance procedures to address the excessive wear and tear, cracks, and anomalies that these structures are exposed to. Ensuring adequate maintenance and repairs demands inspection procedures that often require rope access techniques. Even though it is a common practice, it exposes inspectors to complex [...]

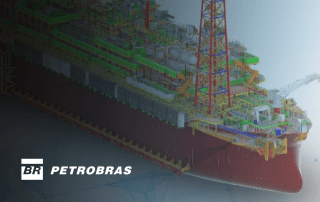

Vidya Technology delivers 4 R&D deep tech projects in partnership with Petrobras

Petrobras is a Brazilian multinational oil and gas corporation, being the largest oil producer in the Western Hemisphere and the 10th largest oil producer in the world. Committed to the development of innovative technologies for the Oil, Gas, and Energy sector they have multiple R&D programs, such as the Petrobras Connections for Innovation. Through this program, they promote a series of initiatives to enhance the integration with the innovation ecosystem. The projects listed below are the result of this collaboration between Petrobras and Vidya for the development of innovative technologies for the O&G sector. Digital Approach for Process Safety [...]

Ocyan Invests in Vidya: A New Chapter in Tech Innovation

Rio de Janeiro, November 21st, 2023. Ocyan, the oil, gas, and new energies service provider announced its first Venture Capital Investment in a startup. The company now has a minority shareholding in Vidya Technology, a deep tech company that develops hardware, software, and artificial intelligence solutions for asset integrity and performance management. Ocyan’s journey with Vidya Technology started in 2020. Since then, Vidya Technology has implemented applications for both the performance management of BOPs (Blowout Subsea Preventer) and the integrity management of FPSOs. In addition, the two companies are jointly developing a hardware for the management of corrosion under insulation [...]

Enhancing Ocyan’s FPSO Fabric Integrity with Artificial Intelligence

September 04th, 2023. Vidya Technology and Ocyan have completed 3 years of partnership since the Digital Fabric Integrity project in the FPSO Cidade de Itajaí. The AI-driven solution combines Digital Twin technology, reality capture, and AI Computer Vision to autonomously locate, map, and identify visual anomalies. With up to 90% AI accuracy and identifying 256% more anomalies than the usual approach, the project was able to transform data, images, and reports into safer and more efficient maintenance actions. Industrial operations face many challenges related to downtime, safety, and productivity. The critical point common to all of these challenges can be [...]