Vidya Expands Digital Integrity Management to New Markets with Scalable Technology

Curitiba, June 13th, 2025 Vidya Technology announces the launch of its Digital Asset Integrity Management Suite, a set of integrated tools that enables full control over the integrity lifecycle from detection to resolution. Combining Artificial Intelligence, Digital Twins, and Spatial Computing, the new solution delivers a contextualized, end-to-end visualization of physical assets, allowing faster and better-informed decisions while enhancing safety, reducing downtime, and cutting operational costs. Originally founded at COPPE/UFRJ, Vidya has become a recognized player in offshore software solutions. Its visual inspection automation technology, which uses computer vision to measure and classify surface corrosion, currently holds 57% of the [...]

FPSO Integrity 101: Challenges, Strategies, and the Path Forward

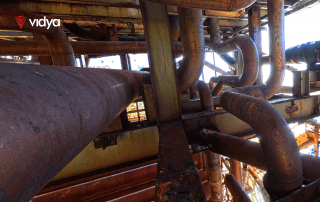

FPSOs (Floating Production, Storage, and Offloading units) sit at the intersection of extreme engineering and long-term economic strategy. Their presence in deep and remote offshore fields enables oil and gas production in places where fixed infrastructure would be impossible. Every component of the vessel is continuously exposed to harsh saltwater conditions, structural fatigue, variable loads, and mechanical stress. Corrosion slowly attacks hulls, risers, and topside equipment. Repetitive motions induced by waves and mooring tensions generate fatigue in welded joints and critical structures. And over time, these forces accumulate. And yet, many operators still treat integrity as a secondary concern [...]

The cost of Ineffective Asset Integrity Management

When a pipe leaks, it’s rarely just a leak. In complex industrial operations, small issues often signal deeper inefficiencies, and when these signals are ignored or mismanaged, the consequences can escalate quickly. From unplanned shutdowns to environmental and reputational damage, the cost of ineffective Asset Integrity Management (AIM) can be staggering. In an industry that depends on reliability and compliance, treating asset integrity as multiple, diffuse tasks rather than a structured, data-driven process is no longer sustainable. Yet, many operators still rely on fragmented systems that hinder decision-making and delay action. But what does it mean to manage asset integrity, [...]

Planning for the Unplanned: Why Temporary Repairs Matter More Than You Think

Temporary repairs are interim solutions applied to damaged or degraded equipment to maintain safety and functionality until a permanent repair can be executed. These kind of repairs are common in every industry where equipment operates under high pressure, temperature, or corrosive conditions, and shutting down operations for full replacement or overhaul isn’t always immediately feasible. Temporary repairs are not meant to last indefinitely, but can be strategic for avoiding production loss, mitigating safety risks, and buying time until a planned intervention can take place. Thus, when does a temporary repair become the safest move? Why Do Temporary Repairs Happen? [...]

Vidya and BRAVA Energia Present Paper at OTC Houston: A New Chapter in Corrosion and Integrity Management

This year, at the Offshore Technology Conference (OTC) in Houston, a new benchmark was set for offshore asset maintenance and corrosion control. Vidya, in collaboration with BRAVA Energia, presented a technical paper exploring a game-changing approach to the industry’s enduring challenge: reducing the risk of corrosion while optimizing operational efficiency in brownfields. Titled "Digitalization of the Corrosion Identification Process Using Digital Technologies in Mature Fields", the paper was co-authored by teams from Vidya and BRAVA Energia, including: Lincon D’Aquila, Integrity and Maintenance Manager at Brava, Otavio Correa, Vidya’s CEO, Jorge Mariano, Vidya’s VP US, and André Andrade, Marketing [...]

Regulatory Compliance in Asset Integrity: What You Need to Know

In large-process industries, entire facilities operate under conditions of high pressure, high temperature, and elevated risk. Within this context, regulatory compliance is not a bureaucratic obligation—it is a technical imperative. Asset integrity, safety, and operational continuity depend on how well facilities meet and maintain regulatory standards, particularly for pressure-retaining equipment and critical infrastructure. This blog explores why Asset Integrity requires regulatory compliance and how operations can benefit from being transparent and compliant. Why Asset Integrity Requires Regulatory Compliance Maintaining the structural integrity of equipment such as pressure vessels, storage tanks, and interconnecting piping systems is essential for mitigating [...]

Las 3 etapas de la Gestión de Integridad de Activos (AIM) en la Energia

La Gestión de la Integridad de Activos (AIM) es un dominio fundamental para las industrias de procesos a gran escala. Esta se refiere a la disciplina industrial que busca maximizar la eficiencia y confiabilidad de una planta de producción, incluyendo múltiples metodologías, sistemas y profesionales de distintas áreas. Este blog explora cómo los líderes de la industria abordan AIM, proponiendo una estructura paso a paso para implementar un programa sólido. No obstante, antes de comprender el estado actual de AIM, se cuestiona: ¿Cómo este dominio evolucionó hasta convertirse en un área tan compleja y específica? ¿Qué es la Gestión [...]

The 3 Stages of Asset Integrity Management in Energy

Asset Integrity Management (AIM) is a fundamental domain for large-process industries. It refers to the discipline that aims to maximize a production plant’s efficiency and reliability, involving multiple methodologies, systems, and various professionals and activities. This blog dives into how industry leaders approach AIM, encompassing a step-by-step structure to implement a robust program. Nonetheless, before understanding the current state of AIM, how did it evolve to such a complex and specific area? What is Asset Integrity Management? Asset Integrity Management (AIM) is the systematic approach to ensure the safety, reliability, and efficiency of industrial assets throughout their lifecycle. [...]

Understanding Asset Integrity Management and its Importance

Asset Integrity Management (AIM) refers to the discipline that aims to ensure industrial assets perform their functions accurately and efficiently throughout their lifecycle, all while maintaining safety and sustainability. In this context, a robust and effective asset integrity management program spans every stage, from asset design to decommissioning, aiming to mitigate risks to the environment, people on the field, and the industrial installation of which they are a part. This blog explores the major challenges of Asset Integrity Management and how the Oil and Gas industry is facing the digitalization of this important discipline. Signs of unoptimized asset [...]

How AI is Enhancing Wind Turbine Integrity

Wind turbines have become the symbol of clean energy production. As global priorities shift toward clean energy sources, the demand for wind power has rapidly increased in the last few years. Still, despite its ecological appeal, wind energy production faces limitations and challenges that require intricate processes and solutions, just like any other energy industry. Fortunately, technology advancements are helping the industry address these pressing issues and operate more sustainably and safely. In this manner, what defines those ‘’pressing issues’’ impacting wind energy operations? The Challenges of Wind Energy Operations As the demand for wind energy grows, so [...]