Unlocking AI’s accuracy and reliability

AI's growth scenario From its early days as a theoretical concept to today's omnipresent reality, AI's journey has been characterized by exponential growth. According to a 2022 IBM research, more than a third of companies (35%) report the use of AI in their business, a four-point increase from 2021. This illustrates a key change in the way we face reality, but different from other technological revolutions: today’s tool learns from its own experience at increasingly higher speed and scale. These tools are programmed to have a human-like thought process. Moreover, they are now a reality in the [...]

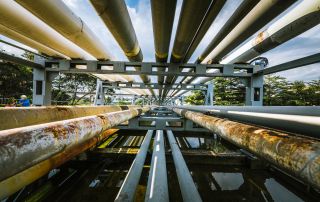

Challenges of Corrosion Under Insulation

Intro Corrosion under insulation (CUI) is a pervasive problem in industrial process units that can lead to serious consequences if left unaddressed. It occurs when moisture becomes trapped between the insulation material and the metal surface, leading to accelerated corrosion. In this blog post, we will explore what CUI is, the risks it poses to process units, and the costs associated with it. What is Corrosion Under Insulation? Corrosion under insulation refers to the corrosion that occurs beneath insulation materials used to protect industrial equipment and pipelines. When moisture is present within the insulation, it creates a corrosive environment that [...]

Exploring Remote Inspection Techniques in the Oil and Gas Industry

Intro The oil and gas industry plays a critical role in powering our modern world. However, ensuring the integrity and safety of assets in this industry can be a very complex and dangerous task. Traditional inspection methods often involve significant manpower and time, along with potential safety risks due to the nature of offshore production processes. In recent years, remote inspection techniques have emerged as a game-changer, revolutionizing the way inspections are conducted in these kind of facilities. In this blogpost, we will delve into the possibilities offered by remote oil and gas inspection, such as drones and 360 cameras. [...]

La importancia de la gestión de integridad de activos para la industria

La gestión de integridad de activos, Asset Integrity Management (AIM) en inglés, representa la capacidad de un activo industrial en desempeñar su función con precisión y eficacia, con tiempo de vida óptimo y seguridad adecuada. La gestión de activos es necesaria desde la fase de diseño hasta el final de su vida útil. Hay que tener en cuenta todas las etapas del proceso para que haya una gestión eficaz para predecir posibles riesgos para el medio ambiente, las personas involucradas y la instalación industrial que forman parte. En este post, exploraremos los principales desafíos de la gestión de la [...]

Transforming Pipeline Inspection with Machine Vision

Oil and gas pipelines are critical operation components that must provide safe and efficient means of transporting energy resources across vast distances. However, ensuring the safety and reliability of these pipelines requires regular maintenance and inspection, which can be a complex activity Traditionally, inspection has relied on the human workforce in the field, who visually examine pipelines for signs of damage, corrosion, or other defects and then fill out reports to indicate anomalies or possible problems. However, this approach is time-consuming, costly, and can be prone to human error. Moreover, it is difficult to inspect pipelines located in remote or [...]

Paper vs Digital Inspections

Intro Oil and Gas operations pose unique challenges to their operations when the matter is inspection and maintenance. Since this kind of activity involves a variety of risks and complexities, it is not uncommon to find field workers filling out paper reports, and walking around the facility looking for potential problems. This is a traditional-manual method, on which oil and gas companies relied throughout the years when performing risk assessments with the goal of preventing potential hazards that could compromise the continuity of the operation. Meanwhile, digital transformation has been disrupting the way things are done with increasingly advanced [...]

Driving safety in Mining through Risk-based Inspections

Intro Risk-based inspections are an important method for driving safety in mining operations. Unlike traditional inspections, which are based on a predetermined schedule, risk-based inspections prioritize areas of the mine that are more likely to be susceptible to accidents or incidents. By identifying and mitigating potential hazards, risk-based inspections can contribute to improving safety standards and reducing the likelihood of accidents. One of the main benefits of risk-based inspections is that they allow mining companies to focus on the areas of the mine that pose the greatest risk to workers and the operation. This means that resources can [...]

How to achieve efficiency in structural integrity management

Intro Structural integrity is one of the key challenges managed in the midst of industrial operations. From oil drilling to mining, the integrity of structures is a determining factor in the proper functioning of this type of operation. In short, structural integrity is the ability of an asset, equipment, or structure to operate without suffering deformation. For this to be possible, the structure needs to withstand its own weight, as well as external influences such as windstorms, storms, and hail. Normally, this kind of asset is built with materials resistant to its load, and in its own construction are [...]

What is Process Safety Management

Intro The oil and gas industry is characterized by the exploration of oil and natural gas in extremely hostile environments generating constant risks to the staff, the environment, and also to the integrity of the plant. Offshore operations are marked by their high complexity, with many processes occurring simultaneously in tens of thousands of heavy assets. In this scenario, operational safety management has the objective of developing internal procedures in order to avoid accidents and provide assertive measures to decision-makers. What is Process Safety? As mentioned before, Process safety management is about developing efficient and effective safety management [...]

The Corrosive Process in the Oil and Gas Industry

Intro Corrosive processes are one of the main challenges for the oil and gas industries around the world. From the extraction process to refining and transportation, corrosion is an ongoing element in oil and gas plants. Besides being a high-risk problem for operators in the field, corrosion is also responsible for a large cost. According to NACE, the cost of corrosion prevention in an industrial environment is around 49 billion dollars, with at least 50% of this amount referring to atmospheric corrosion. In this blog we will talk about the main challenges and impacts generated by corrosion in the oil [...]