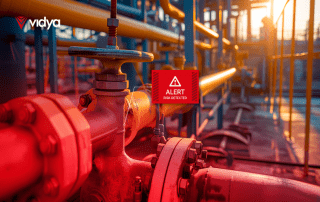

How to optimize Industrial Safety and Risk Management

The International Association of Oil and Gas Producers reported a 36% increase in offshore fatalities from 2020 to 2021. This concerning rise underscores the inherent safety challenges of the industry. Certainly, this sector is subjected to safety threats due to the complex processes and hazardous environments in which it operates. For this reason, high-complexity facilities such as oil and gas need to target safety and risk assessments as fundamental pieces of operational management. But what are the main concerns of the oil and gas industry regarding risk management? Concerns regarding risk management in the O&G Industry [...]

The Future Lies in the Past: Embracing Brown Fields for Tomorrow’s Energy

A 2011 study by IHS Cambridge Energy Research Associates reported that approximately two-thirds of global daily average oil production comes from brown fields and that the percentage is increasing over time. Indeed, it’s evident that mature fields have become a fundamental piece of the petroleum exploration sector, but what exactly are mature fields? According to Parshall (2012), brown fields, also known as legacy fields, are defined by years of production and aging infrastructure. Indeed, for a field to be considered brown, it had to produce more than 50% of its established proved plus probable resource estimates or have produced for [...]

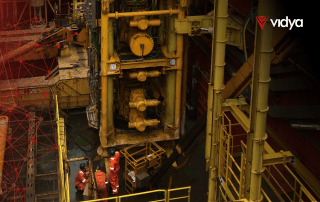

Exploring the Depths: Understanding Offshore Oil Drilling

Until 1894, we didn’t know extracting crude oil from subsea environments was possible. This changed when the lure of offshore production enticed Henry L. Williams and his associates to build a pier 90 meters out into the Pacific — and assemble a standard cable-tool rig on it. Since then, oil extraction has evolved in unprecedented ways. In recent years, new technologies have emerged as powerful tools for addressing the inherent challenges of exploring previously unreachable resources. Indeed, subsea drilling still represents a complex operation that requires advanced techniques and skilled teams to achieve optimal efficiency and safety. And, despite the [...]

How to leverage the full potential of AI Predictive Maintenance

Industrial maintenance is a crucial but challenging aspect of large-scale process industries. Traditional maintenance methods result in expensive, risky, time-consuming, and often inefficient activities. This has led to a growing implementation of digital technologies to optimize maintenance, which made clear the opportunities that these optimized processes offered, like foreseeing anomalies with predictive maintenance for example. However, successfully implementing this maintenance approach requires the integration of different cutting-edge technologies. Despite the complexity surrounding the adoption of predictive maintenance, we need to understand its leveraged opportunities in industrial environments. Why industrial maintenance requires predictive care Industrial maintenance can be a [...]

AI-driven Hull Inspections: Streamlining Safety and Efficiency

Vessels are crucial parts of different industrial operations. Considering this, the ship's main body: the hull, must be regularly inspected to ensure high asset integrity, safety, and efficiency standards. Hull damages such as cracks can lead to oil leaks, which can implicate direct emergency costs that surpass USD 50,000,000 according to Brazil's National Petroleum Agency, which is 100x more expensive than the investment to repair the defects on time (before the accident) not including compensations, fines, and asset depreciation. In this regard, hull inspections are a maintenance procedure that helps energy companies and bulk cargo transporters maintain high safety, compliance, [...]

Smart Hulls, Safe Seas: How to keep O&G facilities efficient

Introduction: Tank and hull inspections are critical for ensuring the safe and efficient operation of oil and gas floating production and storage facilities and tanker ships. The challenges of maintaining hull integrity are numerous, including corrosion, fatigue, and structural damage. In this article, we will explore the challenges of hull integrity management, as well as emerging technologies and approaches that may help address the challenges faced by this industry. Challenges of Hull Integrity Management Managing hull integrity presents a multitude of challenges, particularly when dealing with offshore and remote locations. External and internal care of [...]

What is the difference between AIM and APM?

Asset Integrity Management (AIM) and Asset Performance Management (APM) are concepts that often get confused. Indeed, both focus on enhancing maintenance plans while reducing costs. However, it is necessary to understand which problems they specifically address to visualize the scope of their benefits. In this context, let’s learn about the main differences between these two vital concepts for heavy asset industries. The role of AIM As the name suggests, Asset Integrity Management focuses on the physical integrity of the asset, its purpose is to improve operational safety and maintenance planning. This strategy provides necessary outputs to industries about [...]

Why predictive maintenance isn’t always an answer

Intro Predictive maintenance has proven to be an effective methodology for enhancing the lifespan of valuable assets in the industrial sector, as it allows companies to predict when equipment is likely to fail or stop. This way, proactive measures can be taken to prevent downtime and reduce maintenance costs. Besides that, a November 2021 report from IoT Analytics estimated that the $6.9 billion predictive maintenance market would reach $28.2 billion by 2026. This showcases the immense potential this technology has, allowing companies to optimize their outcomes while reducing downtime. However, if this technology isn’t adequately implemented, [...]

What Digital Solutions are being a game-changer to industries

Intro In today’s rapidly evolving world, digital solutions are reshaping industrial standards for efficiency, safety and innovation. They’ve become a game-changer for facilitating multiple industrial and business related tasks such as process automation, anomaly detection, scenario visualization and decision making. This transformation is not merely a trend but a fundamental change that is rebuilding the landscape of industries worldwide. "Digital transformation is not about technology; it's about solving problems. It's about using technology to make our lives better." - Eric Schmidt, former CEO of Google And, on the edge of Industry 4.0, Digital Solutions are [...]

La importancia de la gestión de integridad de activos para la industria

La gestión de integridad de activos, Asset Integrity Management (AIM) en inglés, representa la capacidad de un activo industrial en desempeñar su función con precisión y eficacia, con tiempo de vida óptimo y seguridad adecuada. La gestión de activos es necesaria desde la fase de diseño hasta el final de su vida útil. Hay que tener en cuenta todas las etapas del proceso para que haya una gestión eficaz para predecir posibles riesgos para el medio ambiente, las personas involucradas y la instalación industrial que forman parte. En este post, exploraremos los principales desafíos de la gestión de la [...]