The recovery in American Oil and Gas production

With the covid-19 pandemic at the beginning of 2020, the oil and gas industries suffered impacts on their production and are now looking for its recovery. The pandemic changed our routine, our lives, and forced us to quickly adapt to a new work model. The need for social isolation was also one of the measures taken to safeguard the health of people around the world. As the disease spread across the world, economic structures began to encounter new behaviors. For the American oil and gas sector, this change was responsible for one of the biggest drops in oil consumption in [...]

Mining and Digital Transformation – A Sustainable Combination

Through digital transformation, mining industries have the possibility of overcoming obstacles through the use of technologies in their operation. Industries today face an extensive path for digitization. The rise of digital transformation has become an inherent necessity in industrial processes, and it is no different in the mining sector. Understand the 5 steps to a successful digital transformation strategy There are many advantages that digital transformation has provided to industrial processes and operations, including: Alignment with decarbonization needs Greater control over resource use and field team management Greater safety for operators These are the 03 main challenges that [...]

IoT Solutions for More Control and Security in Industrial Operations

Technologies driven by Industry 4.0 and Digital Transformation have been helping many industries to adapt to a new model of operation based on digitization, which is establishing itself in the market. Among these new technologies, IoT (Internet of Things) is one that has been attracting attention due to its various applications. The importance of this technology for the industry and its functionalities applied to operations and processes are already well known by a large part of the sector. Many companies tend to adapt to this new scenario so that they can better enjoy the benefits generated by the application of [...]

4 secrets to optimize your Industry Asset Integrity Management

Through digital transformation, asset integrity management has been automated with the use of Digital Twins, IoT, and Artificial Intelligence. The implementation of these technologies within industrial plants is generating surprising results with higher performance and yield rates. Because it is a discipline with a high degree of complexity, especially in industrial plants in the oil and gas, paper and cellulose, petrochemical, and mining sectors, integrity management has been one of the greatest examples of how digital transformation is the path to a smarter future for industries. In this text, we will show 04 points in which you must pay attention [...]

The evolution in Asset Integrity Management

The industries over the last few years have faced the growing importance of using digital systems aimed at the integrity of assets in their operation. The essentiality of the digitalization of this discipline for the maintenance of a continuous, safe process, with better performance indexes, is already known by many managers, and the implementation of new technologies that optimize the integrity of these assets is already part of the digital transformation of large companies. Read: Asset integrity the secrets behind management As much as the subject is already known by the industry, there are still many difficulties in adapting to [...]

Digital Twin and Artificial Intelligence: that’s the secret for better performance

Inspection and maintenance tasks in industrial plants are extremely important for the proper functioning, guarantee of safety, and continuity of an operation. Thanks to Digital Transformation these activities can be enhanced through Digital Twin and Artificial Intelligence. The discipline responsible for managing these activities is known as asset integrity management. Among the main duties of this discipline are: Identification of failure mechanisms Identification of loss of performance in assets Management of inspection and maintenance teams We can understand the essentiality of this discipline for the proper functioning of an industrial plant. However, managing assets can be an extremely exhausting and [...]

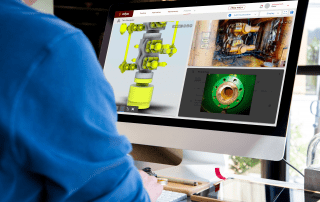

4 Systems in one? See how Ocyan did it using Digital Twin

The history of Vidya and Ocyan Waves began in 2020, and it has been a great journey! Last year we were selected for the Digital Twin: BOP (Subsea Blowout Preventer) Challenge, and today the proof of concept (POC) developed at the challenge evolved into the following amazing project with them! The BOP (Subsea Blowout Preventer) is an extremely important piece of equipment to guarantee the safety of the drilling operation of an oil well. It is composed of a set of valves responsible for closing the well in an emergency, preventing oil leakage. All of the crucial data for operations [...]

Digital Twin is revolutionizing Asset Integrity activities in the industry – but how does it works?

Have you ever come across an article talking about how Digital Twin will change industries? The search for this technology is increasing among many industrial managers, especially the asset integrity ones, and software powered by this solution is the sector’s bet. Digital Twin History The Digital Twin was originally designed by Michael Grieves in 2002, to be used in industries Project Life-cycle Management (PLM). To simply define a Digital Twin, it is the digital representation of an existing object, with the ability to exchange data. In a real Digital Twin, all the data flows from the physical to [...]

The journey of digital transformation for the Mining sector

Since antiquity, mining activity has been present in civilizations, and since then it has played a very important role in the supply of mineral material for the development of tools, technologies, and inputs. The importance of this industrial sector is unquestionable. However, the sector faces several difficulties on its way so that its operation remains profitable, safe, and with the minimum possible environmental impacts. As it is a very complex operation and involves heavy machinery in its operations, it is not uncommon to find examples of accidents or failures that compromise the integrity of operators and the continuity of the [...]

Vidya’s Software New Features!

Vidya Software has evolved over the years, but in 2020 this evolution was greater than ever! With a team of asset integrity specialists prepared to improve our product based on customer insights, and focused in offering the best industrial software in the market for Asset Integrity Management, we’ve developed new and cutting edge important features. Vidya is committed to improving the software and making it a more agile, interoperable and reliable digital solution in the market. Focused on cost-efficiency, Vidya’s team is always developing new ways to increase the productivity of the industrial process. Check out which are these features! [...]